Кстати, здесь есть эта история, но на русском...

|

| Альбом: VM contest 2009 |

The first time I have seen a recumbent bicycle in 2004 in the Finnish camping, we with a family and friends went to Norway in holiday.

The first time I have seen a recumbent bicycle in 2004 in the Finnish camping, we with a family and friends went to Norway in holiday.The unusual design has sunk down to me in memory, most likely it was SpeedMashine HP Velotechnik.

I have recollected it much later, in 2008 when have started to go for a ride on bicycles together with the son 1,5 years old.

Has come to buy thought trike and to put on it a children's seat.

Yes, I knew that:

- In Russia there is no place to go for a ride on the recumbent

- On a border you will not jump

- With storage there will be problems

- Weight more than at MTB

But it would be desirable. Simply desire and interest was .

Theme studying has shown that such devices only in the countries where already there are all conditions for bicyclists are made. I.e. in States, France, England and so on. The Prices too have not pleased, adding to them also the duty and the VAT in general became uninteresting.

In Russia practically there are no such bicycles, there are only enthusiasts who do for itself.

Almost unique resource on the Russian Internet it Velomobile.org

Yes, certainly a variant to bring it himself in other country, for example by the car. Developed also this variant, but as a result has decided to try itself. To make.

First it would be desirable to make in a simple way, faster, more cheaply, temporarily...

But in process of deepening in a theme of questions appeared more and more, and configuration became the basic question. It was necessary to study the best samples of import technics on photos, on manuals... Visits in bicycle shops in cold January days... Material Searches, finding-out of the prices for components...

The first sketches (it is not enough than different from two serial bents)... There was completely an original, author's geometry of a frame and ALL details Later. All details here, except, certainly, standard bike components, original, are made under my own drawings under my order.

Long all it was. In half a year there were the working drawings, the first details were ordered...

Having received well made first details it would not be desirable to do further in a quickly way any more, in a simple way, temporarily... The Degree already could not be lowered.

Only on armchair designing some weeks have left... Was planetary hub, wheels, plugs Further... It is a some time for the coloristic scheme, finding-out of technological features of colouring, reception of already painted complete set for assemblage.

In June has started to test a device. The train upgrade at once has gone, all new problems, bugs, defects emerged...

In July 2009 already could drive.

Most often asked questions in the street:

- What is it? (intonations the most different)

- Probably it is inconvenient so to go?

- And IT is possible back in the NORMAL bicycle to alter?

- Probably the heavy? Poor...

- Are sell in medical shop ?

- Well and why to you did not go for a drive on NORMAL bike?

About trike:

Frame & Geometry

Frame:

The frame is welded from an aluminium profile 40х40х1.5, according to my drawings.

Part for steering system

Rear part with default hub (later will be changed to Shimano Nexus)

20 mm axle hub

Seat

Seat design out left for last moment, did not know how to make better. There were some variants, a frame seat with a mesh, a rigid seat (without smooth bends), a rigid collapsible seat (the back should develop).

At last a variant of a rigid seat with smooth bends of a back. Geometry long developed, did photos of sideways himselfs, measured radiuses and angles of slope. I.e. has made a seat precisely under itself. Already having finished working out of design of the seat, has received from friends the reference to a new bicycle from AZUB ECO. It was pleasant to notice that not only I thought of such design. By the way, at AZUB too an orange bicycle, my favourite colour.

Details to me cut out the laser from 2 mm. aluminium, very qualitatively. All details were ideally suited each other.

The only thing with what it was necessary to tinker bended part on a seat. For this purpose it was necessary to assemble bender for sheet metal.

Bending is not so easy, but it possible:

Ready seat (befor painting):

Rear suspension and child seat

Further it was necessary to invent fastening of the back shock-absorber and fastening of a children's seat (as usually I have left it on then, hoping to make in a place, now I know that anything to leave on then it is impossible, it is necessary to project at once all design).

Here temporary assembled:

Siemens fitting for 35 mm. tube suited well:

Next solution:

Painting

After I has disassembled trike to a detail and has brought on painting.

Have painted with a powder two colours: orange under a varnish and the matte black.

It has turned out remarkably!

Then there was a design assemblage.

Seat pad

On a seat I ordered a pad in a specialised workshop which is engaged in tuning of salon of motor vehicles.

By design working out the decision from HP Velotechnik (two separate parts) has been partially borrowed.

The son of the friend holds an seat

Chain idler

At first I fondly believed that a roller not the most important part of a design. But after first riding it was found out that it is necessary to prosecute this subjects seriously.Then there was a long experiments with a chain roller (which proceeded till August).

Combined chaintube (experiment)

Experiment was successful, it works.

Safety flag and console with mirror

I have applied the cheap automobile aerial to a flag from fibreglass (the problem with fastening at the same time has been solved).

The mirror from the Japanese off-road car has been cheaply bought on automobile dismantling and together with a front lamp and AirZound has been fixed on an aluminium tube which can easily fixed in trike.

Some broken parts (after ridings) and repaired frame

Trike top (future project)

In august 2009 we went in holiday to Finland ( with trike).

New project: "Reah Trike-2"

Now I assemle trike the new project. I can not even assume yet, whether that has conceived will be successful. But if it will be, in new trike there will be some technical solutions which I yet did not see till now at other manufacturers of recumbents.

One of decisions will help to solve in a new fashion a tike storage problem .

But while I will not speak is better more than have told.

Coming soon...

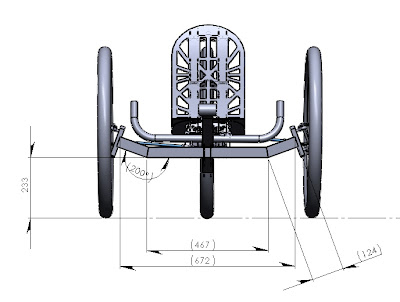

Размеры первого трайка

Информация о соответствии маркировки алюминия по ГОСТ и по ISO :

Алюминий

1 comment:

Very interesting and I admire your efforts. I have a Trice QNT but don't venture out in snow :0)

Post a Comment